COVID 19: Conducting Robust Remote Audits

Learn More

The recent Coronavirus pandemic has emphasized the benefit of being able to work remotely and still accomplish what needs to be done. One response to the Coronavirus pandemic is an increase in remote (electronic) auditing. Remote audits include desk and virtual audits. The benefit of remote audits are that they save time, money and logistical effort. They can also be used when onsite audits are problematic for some reason that is outside of the control of the auditing organization.

The concern is that while remote audits can be good at evaluating the structure of a quality management system (QMS), if not designed properly they are prone to miss compliance issues that might indicate that the QMS is not well implemented. There is also the risk in conducting remote audits in lieu of onsite, in that certain nonverbal cues may be missed and the auditor may draw incorrect conclusions. So the benefits of performing remote audits must be balanced against the risks.

Why You Should Attend:

Virtual audits are closer to onsite than desk audits in that they include real time engagement with the auditee as documents and records are reviewed, such as using video or teleconferencing technology, as opposed to being face to face. Desk audits, on the other hand, are a combination of discrete actions as documents and records are requested and then reviewed offline by the auditor. Interviews are scheduled and held over the phone or through teleconferencing. Both virtual and desk audits may be conducted as standalone audits or in conjunction with an onsite audit.

Areas Covered in the Session :

- How much and which documented information should be requested

- What is the process for planning and conducting remote audits

- What technology is available to assist in conducting remote audits

- Knowing when to consider a virtual audit vs. desk audit

- Pitfalls to avoid when considering remote auditing

Who Should Attend:

- Quality Departments

- Quality Engineers

- Quality Auditors

- Supply Chain Departments

- Manufacturing Departments

- Engineering Departments

- Production Departments

- Documentation Departments

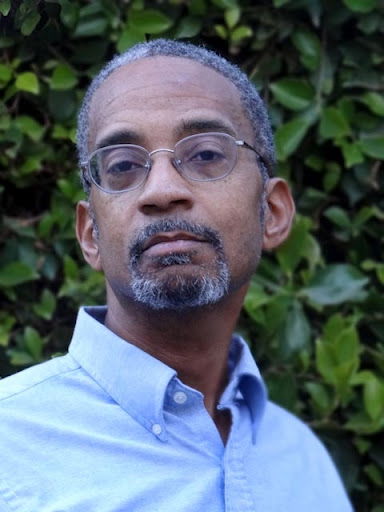

Course Director: LANCE B. COLEMAN

|

|