Managing Product and Process Risk through Failure Mode and Effects Analysis (FMEA)

Learn More

Conducted early in the process development cycle, the Failure Modes and Effects Analysis tool is used to identify risks and then adjust the manufacturing or service process to reduce the identified risks and improve quality. Attendees will learn practical application of Failure Mode and Effects Analysis (FMEA) as it is applied to product, process, or system design.

The course will teach identification of potential failure modes, the risk attached and indicate their relationship to product design or manufacturing process, along with their effects, if known, on the end use of the product. Root cause analysis, risk mitigation and assessing residual risk will be addressed as part of the FMEA process. Also to be discussed are FMEA history, methods, types, responsibilities, documentation, implementation, and software. Attendees will receive an FMEA excel template that they can customize and begin immediately using.

Areas Covered in the Session :

- How to Manage designated personnel with the skills to conduct and complete an FMEA of products or processes

- Define types of FMEA’s

- The important benefits of FMEA

- Be familiar with components of FMEA

- Understanding process requirements

- How to select cross-functional teams

Who Should Attend:

- Design Managers

- Design Engineers

- Manufacturing Personnel

- Process Managers

- Process Engineers

- Quality Assurance Personnel

- Reliability Research Personnel

- Development Department

- Safety Engineering Personnel

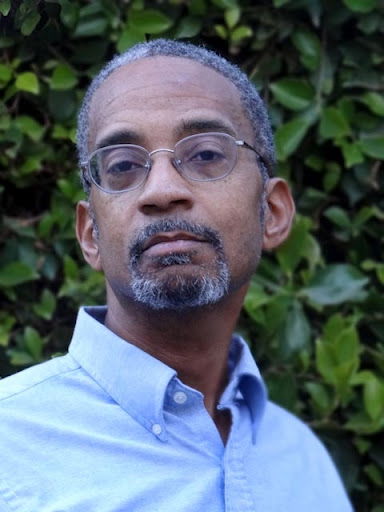

Course Director: LANCE B. COLEMAN

|

|